Welcome to our first news letter – Our new website and the last 6 months at IMS Group-22nd July 2015.

Firstly we have redesigned and launched our new website. We have put a real focus on the specialist support services we supply to the facilities management and building services industry and have attempted to provide a more in-depth overview of IMS Group.

We thought we would start our first newsletter with an overview of the last 6months.

IMS Building and Fabrications:

IMS Building and Fabrications started the year on a high by winning the prestigious Hackney Design Awards for their work on transforming an old dilapidated single storey building previously used by an upholsterer in Hackney into a delightful modern living 2 bedroom 2 bathroom home over 3 floors, titled “the ginger bread house”.

The building was purchased by a young architect for her to not only live in but be a display/advertisement for her newly formed architectural firm.

The original building was replaced with a taller building to maximise the available space on 4 x 9meter plot. IMS Building and Fabrications, where the perfect solution to enable this complex vision to become a reality. With their years of experience and ability to be problem solvers whilst works are commencing, IMS Building and Fabrications were able to deliver a modern living home, whilst being compassionate with its surroundings.

please click here to read published article

please click here to read published articles

Other works by IMS Building and Fabrications:

IMS Building and Fabrications came to the rescue of a high profile national television studio that was suffering numerous leaks. The roof was found to be leaking from several different areas and was causing serious disruptions to live studio feeds.

Due to the serious logistical & operational issues and problems for these critical works, IMS Building and Fabrications had to think outside of the box with regard to standard roof repairs and used an innovative new product. These works were planned & executed with zero disruption to the client.

IMS Building and Fabrications were tasked with the demolition and rebuild of a vital pump pit lid within a busy 24 hour car park within Canary Wharf. The lid is located in the exit of the car park and the quantity of traffic has seen the lid and the tray warp over time, leaving the lid unmoveable and the vital pumps not being able to be serviced. The works were performed after 8pm on the weekend to minimise the effect on the car park. IMS Building and Fabrications did not only complete the works ahead of schedule but also put in a place a traffic management system to ensure that IMS operatives, the client and the public were safe at all times.

IMS Building and Fabrications are currently working on the renovation of an English Heritage listed Bomb Blast Wall within a Central London Iconic Government Building. More details about these works with images will be issued upon completion of the works

Environmental

The last 6 months have seen IMS Environmental division as busy as ever. With its expanding PPM contracts in place and continually being added throughout the country this division has seen a rapid growth for drainage maintenance works and kitchen extract and associated ductwork disinfection. IMS Environmental offers a unique process of works for drainage maintenance by breaking pipe work and coring the stacks whilst catching the scale, as opposed to the normal method employed by our competitors of just jetting through stacks with a van pack, which tends to just put the blockage further down the line causing more issues later on. This maintenance method will reduce the amount of call outs if our recommended regime of coring is followed. Obviously no amount of maintenance will prevent blockages when foreign bodies are put into the system. This year alone we have attended call outs and removed the following

- A McDonalds Happy Meal toy managed to block an entire system over two floors in a central London, Government occupied, historical building.

- Endless amounts of paper towels which do not degrade have been found in occupied buildings throughout the UK

- Congealed catering fat, oil and grease being mechanically removed before it was released into the sewage system

- A water leak within a London city bank building causing damage to the carpet tiles. IMS Environmental division were called to dry the area out and replace the carpet tiles

IMS Environmental received a call from a very distressed customer who had an issue with a high concentration chemical smell spreading out over two floors of a Government building within central London. The client’s current drainage contractor was unable attend site within a satisfactory time to resolve the issue. IMS managed to send in a team of operatives to investigate within two hour. Upon arrival the IMS operatives found the strong smell was over two floors, the odour was so strong that the employees in the building were having to wear goggles and facemasks. IMS operatives used a CCTV camera to enter into the drainage system and found a build up of a mixture of cleaning chemicals stuck in pipework between the floors due to a blockage of hand towels. The mixture of chemicals had reacted to each other causing this smell. IMS removed the pipe work below the blockage, and pushed the blockage and chemical build up out of the pipe work into containers for safe disposal of the chemicals. IMS then flushed the system with high pressurised water and sprayed the area in a neutralising agent to remove the chemical smell.

IMS Environmental also recently performed air quality testing throughout a commercial bakery in Croydon ensuring the air quality was not putting the client’s workforce at risk.

IMS Environmental have had a long standing Air Quality and Water Sampling and Analysis contracts at a central London Government occupied building renewed for another year.

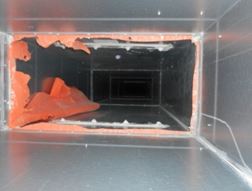

IMS Environmental were employed to complete a condition survey of the Kitchen Extract System and Associated Ductwork within a relatively new iconic central London multi occupancy building. The ductwork was found to have a severe lack of access hatches meaning that future maintenance cleaning regimes would not be possibly. Where access to the ductwork was gained it was found that no pre-clean had taken place and evidence of the original plastic packaging of the ductwork was found to still be in place. All the finding’s and recommendations to ensure that they adhere to TR19 Regulations were passed to the client in a 45 page report.

IMS were tasked to complete a refurbishment of a water cooling tower on top of an iconic building in Canary Wharf. With our team of specialist fabricators IMS Environmental were able to ensure that the Tower met the requirements of a recent inspection.

Mechanical & Electrical

IMS M&E division has been working on some exceptional high profile projects within English Heritage buildings. Some of these projects have included

Replacing Sewage Ejectors throughout a Central London operational Government building that is an English Heritage Site

Replacing the 312 non-energy efficient radiators with bespoke designed energy efficient radiators that sympathise with the original design of a Central London operational Government building that is a English Heritage Site. For contractual reasons we are unable to show any images of these works

IMS M&E division have been winning numerous pump servicing contracts throughout the last 6 months and have replaced numerous pump sets within Government, Education, Healthcare and Financial buildings.

Fire Protection Systems

IMS Fire Protection Systems division has been completing fire stopping on a major Healthcare PFI building for the past 18 months. This large project has seen IMS working alongside their client, the NHS Trust, Project Management company (who completed the Survey), Warrington Fire Consultancy and the local fire officer. The project consisted of IMS working in unison with the Project Management company.The Project Management company would survey a zone of the building, IMS would price for those works within a 48 hour period and works would commence within 72 hours of the completion of the survey. This speedy turnaround was necessity to ensure that the buildings critical areas were compliant within the deadline set by the local fire officer.

The local fire officer stated that the fire stopping completed in the critical zones are of the highest standard that he has seen in the industry. Due to the quality of the work and the dedicated management systems used on this site, IMS was awarded the fire stopping in the non-critical areas. The size of the location and condition of the fire compartmentalisation of the original PFI build means that this two year project will be completed on schedule in the autumn of this year. So far over 250 zones have been surveyed, priced and completed within the set time frames

IMS Fire Protection Systems division were asked to perform an inspection/service of all the Fire and Smoke Dampers and inspection of fire doors in a multitude of school and nursing homes in the Greater London area. This work was completed on behalf of a major Facilities Management company. IMS Fire Protection Systems divisions did not only complete the servicing/inspections within the tightest of deadlines to ensure the sites were not in breach of building regulations, but also completed onsite training for the Facilities Management company, so that they could incorporate visual checks in their weekly and monthly onsite checks. A full regime is now in place for IMS Fire Protection Systems Division to perform annual inspections/servicing.

Failed Fire dampers due to lack or insufficient Fire Stopping

Failed Fire Damper due to being propped open by a foreign object

Replacement hinge badly fitted to door and incorrectly fitted hinges and missing screws

Both cases reduction the function of the fire door

Void in the Door Frames The removal of door and the failure to undertake any form of repair has left significant voids in the door leaf. This will significantly reduce the doors performance in the event of a fire incident.

Gap between the door leaf and frame are to great

IMS Fire Protection Systems performed critical fire stopping to ensure that the grand opening of a 5 star hotel within an iconic central London building was not compromised due to alterations made during the building that affected the buildings Fire Compartmentalisation.

IMS Fire Protection Systems has recently won the 6 monthly servicing/inspections of the Fire and Smoke Dampers within two NHS Buildings, with a combined total of over 5,000 dampers within the two locations. IMS Group are able to inspect each damper to ensure that it works sufficiently and is compliant with the required regulations and produce a detailed itemised report for each site will be produced.

Fire Damper failure poor condition causing the blades to fail to shut

Fire Damper failure due to missing blades on Dampers

I hope you have enjoyed reading our latest newsletter. IMS group is a professional specialist support service provider, supporting the facilities management and building services industry. With four specialist divisions: Environmental, Mechanical & Electrical, Building and Fabrications and Fire Protection Systems, IMS provide these services from four offices in London, Essex, Hertfordshire and the South West.

If you would like more information on how IMS Group can assist you please feel free to contact us directly on info@imsgroup.eu